EDP Systems For Success

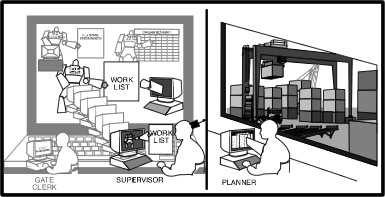

Figure 8

This simple concept will be used over and over in computer applications. The concept can be applied when a task can be identified:

- Where clear human management direction is possible; e.g. put containers in the spots identified by the planner.

- Where independent judgement exercised by the computer is clear; e.g. don't assign a container to a spot when a container is already there.

- A task that is currently distributed to lower level supervision that would be more efficient centralized in the computer.

Short moves

It is not unusual when a yard handling equipment operator reaches a bottleneck to wait until the bottleneck has cleared before continuing work. For instance, if the quay crane is moving hatch covers, all of the equipment operators assigned to the quay crane will soon be idle. This is the result of several factors normally present in a marine terminal:- The segregation of the equipment operators into work gangs or pools under a single gang supervisor. The supervisor and the work gang is usually assigned to a single vessel crane or gate service.

- The preplanned commitment of a gang to a lengthy work list. The gang is usually given work assignments for between several hours to a shift. It takes a long disruption before the work list is abandoned and another commitment is made for the gang.

- Management folklore that encourages handling a container only once to reduce costs.

This same concept extends to the discharge operation where the quay crane is generally much faster than the land-side handling equipment during an on-deck discharge, and much slower during a below-deck discharge. When the land-side handling equipment starts to lag the quay crane during the on-deck portion, the computer system will reassign a few containers to intermediate deck positions near the quay crane. The productivity of the land-side handling equipment is effectively raised to match that of the quay crane. The list of containers not in their prescribed location is saved by the computer for rehandling at a later time. Later, during the below-deck operation when the handling rate of the quay crane has slowed, the computer will direct the movement of the the containers to their proper location.

In this case, some containers are double handled. Instead of reducing the number of times a container is handled, the yard operation and the vessel operation are matched to achieve a higher overall throughput.